Bioplastics Materials

Understanding Raw Material Sources of Most Bioplastics

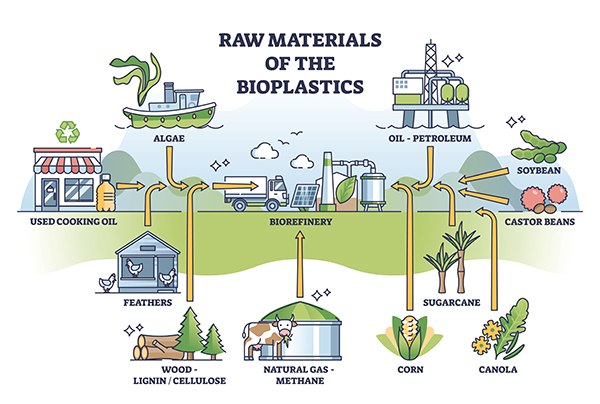

As a reminder, bioplastics are plastic materials produced from renewable sources. Bioplastics uses sources including the sun and the wind. They also use naturally produced and renewable biomass sources such as vegetable fats and oils, corn starch, straw and more, including recycled food waste. Some bioplastics are generated by processing directly from natural biopolymers such as carbohydrates (sugars) and proteins, while yet others are chemically synthesized from polysaccharides (sugar) derivatives and lipids (fats) from plants or animals. That’s a lot to digest, pun intended. Let’s dissect this a bit.

Just as crude oil is extracted from the earth, bioplastics are produced by extracting polymers from biomass, organic material made by living organisms. Yes, you read that right, polymers needed to produce plastics are naturally occurring materials! Examples of biomass include corn, sugarcane, vegetable oils and other edible sources. These are considered first-generation (readily fermentable) biomass. Second-generation (non-edible biowastes) biomass includes wastes from agriculture, industry, cooking, food, foresting, and municipal landfills. Third-generation biomass types refer to seaweed, cyanobacteria, and microalgae.

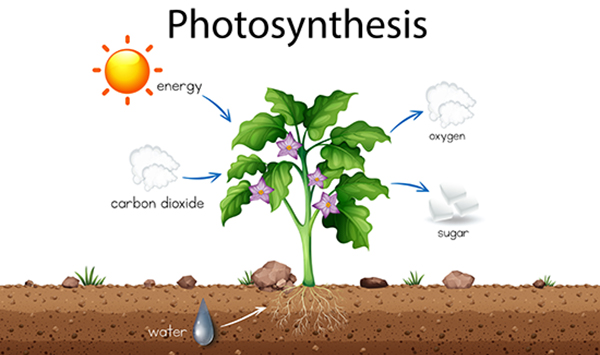

You may be asking yourself how corn and sugarcane, etc., are considered living organisms. A seed, even though dormant, contains live, active cells, therefore is a living organism. Plants are nourished and produce their own food from air, water, and sunlight. Let’s take ourselves back to high-school biology….

Wood is a product of trees, another live plant. It is the most common form of biomass. Wood is used for fuel and wood processing yields byproducts, such as sawdust, bark, branches, leaves, and needles, which can be converted as biofuels or bioproducts. Forestry residue from logging timbers and wood processing for pulp, for example, result in residues that can be converted. Collecting dead, diseased, or other unmerchantable trees after a timber harvest can be used for bioenergy. Likewise, excess biomass on the millions of acres of forests reduces the risk of fire and pests, while aiding forest restoration and vitality.

Food crops and residues from agriculture are additional sources of biomass. Some crops are grown as dedicated energy crops on land not suitable for traditional foods crops such as corn or soybeans. Some are bamboo, sweet sorghum, tall fescue, wheatgrass, and others. Some include more woody crops like fast-growing hardwood trees such as hybrid poplar, silver maple, green ash, black walnut, sweetgum, and sycamore. An added benefit of the energy crops is these species often improve water and soil quality, and wildlife habitat. Agricultural crop residues include stalks and leaves (including corn husks and cobs) wheat straw, oat straw, and more. As a side note, the sale of these residues to biorefineries yields another form of income for the farmers.

Yet another source is oil-rich algae, such as seaweed. Sunlight and nutrients create biomass containing lipids, proteins, and carbohydrates which can be converted into biofuels. These can also be sourced from treated industrial wastewater, municipal, agricultural wastewater, or water generated from oil and gas drilling operations. Organic components of municipal and industrial wastes are other sources of biomass. Even the fumes from landfills (which contain methane, the main component in natural gas) can be used as a biomass energy source.[1]

So how does this all work? The conversion of sugars into plastics typically involves a two-step process: fermentation and polymerization. Here’s a general overview of the process:

- Fermentation: Sugars, usually derived from plant biomass, are first fermented by microorganisms such as bacteria and yeast. The fermentation process converts sugars into intermediate compounds like organic acids and alcohols.

- Polymerization: The alcohols and acids are further processed though a polymerization reaction to form polymers. Polymerization is a chemical reaction in which small molecules called monomers join together to form a larger molecule known as a polymer. The process involves the bonding of monomer units through covalent bonds, resulting in a long chain or network-like structure. Some of these polymers are not only bio-based but also biodegradable such as PLA and PHA.

Polymerization reactions can occur through different mechanisms, the two most common being addition polymerization and condensation polymerization.

Addition Polymerization: In this type of polymerization, the monomers add to the growing polymer chain one at a time without the formation of any byproducts. The reaction is typically initiated by a catalyst, heat, or light. Addition polymerization is commonly used for the synthesis of synthetic polymers like polyethylene, polypropylene, and polystyrene.

Condensation Polymerization: In condensation polymerization, the reaction involves the formation of covalent bonds between monomers, accompanied by the elimination of a small molecule, such as water or alcohol. The byproduct is typically formed when two functional groups from different monomers combine and release the small molecule. Examples of condensation polymers include polyesters (PET) and polyamides (Nylon).

The choice of polymerization method depends on the specific monomers and desired properties of the the resulting polymer.

In a previous item in our series on “The Planet” we stated we were smart enough to create plastics, we’re smart enough to manage it. With all this technology, with all these advancements, and with all these natural resources, managing every aspect of plastics is attainable! We must be wise and circumspect with continuous advancements in all realms of plastics creation and recycling. This requires all participants to come together. From those with a contumacious desire to obliterate all plastics to those who wish to prolifically improve processes towards a better world with plastics, it is of utmost importance to seek solutions, sustainable solutions for all.

We will continue to provide information that will help to educate or share current trends. Please check back regularly for new content.

[1] Biomass Resources | Department of Energy

(Additional Source: Wikipedia)