Benefits of Chemical Recycling

Can Managing Plastics Improve the Benefits of Chemical Recycling?

Our series on “The Planet” previously presented a brief overview on chemical recycling. We continue with pros, cons, and what is necessary to improve the value of this viable option in recycling. One of the disappointing facts of recycling is that very little recyclable waste is actually recycled. Chemical recycling can improve the volume of waste recycled and reduce the volume of waste headed to landfills. More facilities, increased development, and innovative technologies are necessary. So, how do we attain these things to encourage progress?

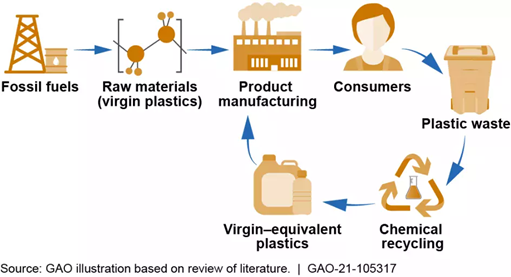

Copious potential for developing technologies in chemical recycling excites the chemical industry. The use of plastics has proliferated since the WWII era. Mechanical recycling was introduced in the 1970’s when initial concerns about plastic waste began to arise. Although mechanical recycling aids significantly in the effort to reduce plastics in landfills, it has a long way to go. Chemical recycling, or advanced recycling, can significantly contribute to the reduction of plastics in landfills. The substantial quantity of energy contained within polymer chains of plastics is significant and the impact of this resource has not been fully embraced. Chemical recycling has the potential to unlock this energy. This energy produces high-quality raw materials, in fact, such high quality it is indistinguishable from new plastics! Chemical recycling decreases the overall need for fossil fuels, thus fewer CO2 emissions.

So, what’s holding us back? Chemical recycling was first introduced in the 1950’s but saw little development worldwide until more recently. According to Crain Communications it was around 2003 that this sector began to heat up. In many respects, advanced recycling technologies were developed to convert hard-to-recycle used plastics into fuel. More recently, the focus of the technologies has changed with a goal for a circular economy. This means generating new plastics that can be recycled again and again. U.S. advanced recycling facilities are ramping up with plans to divert 7 billion pounds of waste from landfills, equivalent to 28,000 Statues of Liberty.

Chemical (advanced) recycling is often referred to as a complement to mechanical recycling as the initial sorting stage is required for both. Essentially chemical recycling is able to recycle all the plastics that mechanical recycling can’t. Sorting technologies have begun to employ artificial intelligence increasing efficiency in automation. Other advanced technologies sort materials by identifying their molecular vibrations. This is key due to the challenges with recycling contaminated or complex plastic products. When complex plastics are separated by identifying the molecular makeup, they are available for advanced recycling. The effectiveness of chemical recycling along with technological developments has the potential to greatly reduce landfill waste! An additional benefit is these complex plastics can be recycled over and over again!

Chemical (advanced) recycling is often referred to as a complement to mechanical recycling as the initial sorting stage is required for both. Essentially chemical recycling is able to recycle all the plastics that mechanical recycling can’t. Sorting technologies have begun to employ artificial intelligence increasing efficiency in automation. Other advanced technologies sort materials by identifying their molecular vibrations. This is key due to the challenges with recycling contaminated or complex plastic products. When complex plastics are separated by identifying the molecular makeup, they are available for advanced recycling. The effectiveness of chemical recycling along with technological developments has the potential to greatly reduce landfill waste! An additional benefit is these complex plastics can be recycled over and over again!

Heightened concerns remain surrounding the processes applied with chemical recycling. Some question if we aren’t trading one problem for another. For example, we may produce fewer virgin materials from fossil fuels, hence less carbon emissions, but will the energy needed for the recycling and purification processes produce more carbon emissions? Or less? Will chemical recycling generate hazardous chemicals, and if so, what happens to the hazardous waste? Will manufacturers need to adjust for cost and performance, i.e., virgin material cost vs recycled material cost and will machines operate the same with recycled materials?

Let’s examine these questions. Any reduction in fossil fuel usage decreases carbon emissions. Recycling is an effective means of reducing fossil fuel usage, but recycling processes need energy to run. If a recycling facility uses renewable energy sources, that heightens the effectiveness of recycling. For example, recycling aluminum cans conserves energy at around 94%. If the recycling facility is running on renewable energy, the effect is extremely eco-friendly.

Another point of interest is transportation. Both fossil fuels and recyclable materials need to be transported. Gas-to-energy landfills harness methane, which is converted to renewable natural gas and is used to power vehicles. Once again, renewable resources reduce the need for fossil fuels and aids in reducing the carbon footprint in the transportation industry.

Chemical recycling has a lower overall carbon footprint compared to end-of-life alternatives such as landfills and incineration. One of the oldest methods of chemical recycling is Pyrolysis, which utilizes a no oxygen environment. It cannot burn without oxygen so there is no hazardous chemical release in this process. Additionally, advanced recycling facilities are subject to the Clean Air Act, state, and local authorities. They must monitor and report or they can be fined.

Companies must balance operational costs with sustainable investments because consumers are demanding that their governing entities manage climate change problems. The agencies involved will explore and enact laws that will impact businesses. Large corporations lead the way in collaboration by investing in new technologies. However, while big money is needed and regulations are highly valuable, a unified approach among communities may be best. It seems clear that this starts at collection. That implies individual effort. Individuals can ignite powerful programs, and this is extremely important towards the best for all. Plastics must be managed. Plastic is not bad. Previous articles highlighted the necessity of plastics. The real problem is unmanaged waste.